_This recap will be a few days late as I currently do not have any progress pictures. In the mean time here is a video:

_Visible progress is starting to slow down as we are focusing more on finish work on the chassis. In order to get to the more trick areas to weld, we had to flip the chassis on it's side.

_

We also fitted in the quick jack bar, thus tackling one more rule from the rule book.

_

_Last big update, we took our old oil and water catch cans and shortened them to the correct specification for a 250cc engine.

_Reference object also included to give an idea of the new height.

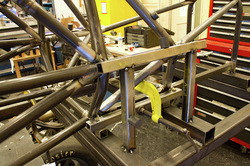

_We are pushing hard to get all the pieces of the chassis welded in place so that we can get the chassis painted. In the last week a number of tabs and hardware were added to the chassis, yet there is still a lot more to go.

_

Front A-arm tabs boxed in and front shock and bellcrank tabs fitted in place.

HVE enclosure welded and fitted in place.

Impact attenuator anti-intrusion plate fabricated and in place.

Radiator fitted, front detail.

Radiator, side/rear detail.

Exhaust system initial placement.

All that remains of FH1 - space frame, seat, body panels, and a steering rack.

FH1 has lived quite a successful life, first achieving 6th place at Formula SAE West in 2006, then later on achieving 3rd place at Formula Hybrid in 2010. It's spirit will live on in FH2 (along with it's ICE, electric motor, and various other parts). A sad but necessary fate, as we are lacking in time and money to construct every single part on FH2.

The past on the right, the future on the left.

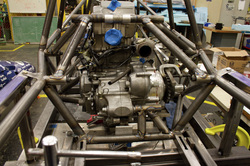

During this week much more final welding was completed, and the IC engine was successfully situated in FH2's chassis

Engine situated in its new home.

The electric motor has also been initially positioned, but a few more modifications are required before the mounts can be fully welded in.

Well this was a sad day. :( We are tearing down FH1 in order to reuse some of the components. The removal and cleaning of parts began today and some will be needed for jigging in tabs for the new chassis. For example, the engine will be used to place the mounts properly. At the same time its exciting to be at this point already, and that means we are that much closer to having FH2 done.

Before....

After...

Look at all those zip-ties! Nasty!!

This weeks focus was primarily on fabricating and installing suspension and steering chassis parts, like tabs and supports.

Throwing sparks with the MIG Welder

Steering wheel & shaft support in place.

Rear tabs tacked in place

Front tabs too

A portion of our electrical energy accumulator

It is hard to visualize the amount of progress that has been made this past week, mostly because the chassis was all tack-welded together last week. Much welding has been completed on the chassis, as well as a number of machining projects. Here are a few images that sum up what has been accomplished:

Lots of lathe work this week, making bushings and mounts.

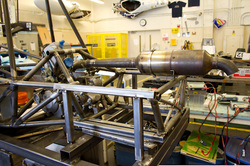

The steering assembly is almost finished, all that is needed is welding.

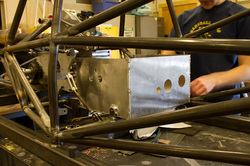

Aluminum gas tank fabricated and positioned. It's mounting tabs just need some final welding, then it's onto fitting sensors, a fuel sight tube, and a fuel cap.

_

A lot of things happen every hour we are in the shop, and a lot of it does not get mentioned in our blog posts. To try and cover the missed details in our weekday posts, I will be posting weekly recaps.

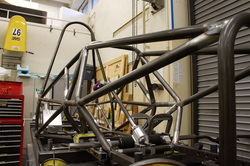

Week 1 saw an incredible amount of progress. By the end of Saturday, with 26 hours into the build, the main chassis tubes have been tack welded together.

Chassis coming together nicely!While a lot of focus was put on getting the chassis together, a lot of other pieces were being churned out on the mills and lathes.

_While a lot of focus was put on getting the chassis together, a lot of other pieces were being churned out on the mills and lathes.

_Locker full of parts: aluminum gas tank, push rods, steering tie rods, suspension tabs, engine mounts, bell cranks, and some non-formula hybrid items that have found their way into our cabinet.

_While there aren't a lot of pictures, the amount of work-hours represented by each photograph, put in by our dedicated team members is numerous. Lets see if we can keep this pace up as the quarter progresses.

_I can't even begin to say how much Accurate Tube Bending helped in making our build a cinch. However, due to a slightly mis-mounted front hoop quite a bit of entropy was generated in order to make the rest of the tubes fit properly, if you know what I mean. Haha. We're getting there, only a few more tubes to go.